| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Place of Origin : Guangdong, China

Model Number : YYI-1

Brand Name : YYI

Packaging Details : Bubble bag+ standard export carton / wooden box /according to customers'demand

Supply Ability : 10000 Piece/Pieces per Week

Price : CN¥9.31-49.79/pieces

Type : Rapid Prototyping

Material Capabilities : Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Plastic.Nylon,Resin,Metal Powder

Micro Machining or Not : Micro Machining

Material type : Plastic,metal

Metal material : Nylon,Resin,TPU,ABS,PP,ASA,PC,Peek,etc

Plastic Material : Stainless steel, aluminum

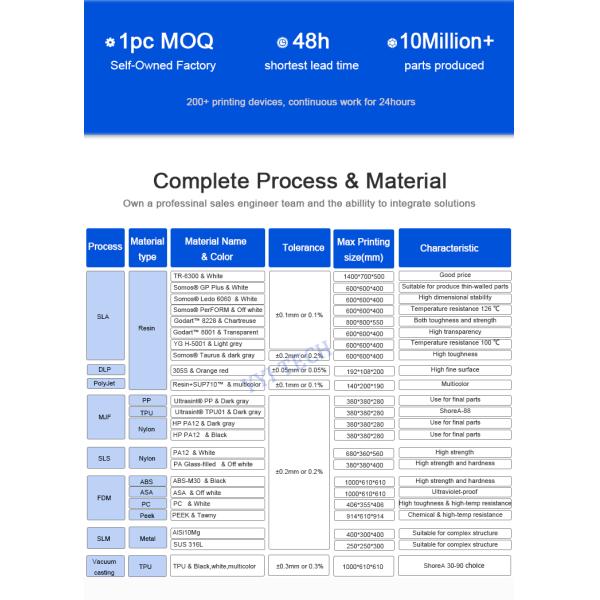

Process : MJF,SLA,SLM,FDM,SLS,Polyjet,DLP, Vacuum casting

Surface finish : Sandblasting,Painting, Coating,Coloring,Plating, Polishing,etc

Quality Control : 100% Inspection before delivery

Usage : Auto-motorcycle,robot,crafts,Appliances,Medical industry

Drawing Format : STP, IGS, STL, ETC

Max width : 1400MM

Tolerance : +/-0.05mm~0.1mm

Port : Guangzhou, Shenzhen

Our Dental Resin Vacuum Casting & PP Material 3D Printing Service combines the precision of resin-based vacuum casting with the versatility of Selective Laser Sintering (SLS). Designed for the dental and medical industries, this service delivers high-accuracy dental models, aligner molds, surgical guides, and durable prototypes.

By integrating resin vacuum casting and SLS 3D printing, we provide cost-effective, scalable solutions for both one-off prototypes and small batch production. With biocompatible resins and PP plastics, this service ensures safety, durability, and clinical accuracy for dental applications.

| Feature | Details |

|---|---|

| Printing Technology | SLS (Selective Laser Sintering), Vacuum Casting |

| Materials | Dental Resin, Polypropylene (PP), Medical-Grade Resins |

| Accuracy | ±0.05 mm – ±0.1 mm |

| Layer Thickness | 0.05 – 0.2 mm |

| Build Size | Up to 600 × 600 × 600 mm |

| Mechanical Properties | High strength, biocompatibility, chemical resistance |

| Surface Finish | Smooth, medical-grade polish or textured (customizable) |

| Production Volume | Prototypes, low-to-medium batch production |

| Lead Time | 7–12 business days |

Precision Dental Solutions – Ideal for dental models, aligners, and surgical guides.

Dual Process Flexibility – Vacuum casting for resin replicas + SLS for functional PP prototypes.

Biocompatible Materials – Safe and suitable for medical and dental applications.

Durability – PP ensures impact resistance and chemical stability.

Rapid Prototyping & Production – From single pieces to small-batch runs.

High Accuracy – Ensures clinical precision with ±0.05 mm tolerance.

Dental Clinics & Labs – 3D-printed crowns, bridges, aligner molds, and training models.

Medical Device Prototyping – Biocompatible parts for clinical testing and validation.

Vacuum Casting Replicas – Cost-effective resin duplicates for dental molds.

Custom Healthcare Products – Patient-specific medical tools and orthodontic solutions.

Industrial Prototyping – PP material parts for durable medical equipment housings.

Digital Dentistry Growth – Increasing adoption of 3D printing in dental clinics.

Hybrid Manufacturing – Combining vacuum casting and additive manufacturing for efficiency.

Biocompatible Materials – Rising demand for medical-grade resins and PP plastics.

Personalized Healthcare – Shift toward patient-specific dental and medical solutions.

Automation in Dentistry – Integration of AI + 3D printing for smarter workflows.

Q: Is dental resin safe for patient use?

A: Yes, we use biocompatible, medical-grade dental resins suitable for clinical applications.

Q: What is the benefit of combining vacuum casting with 3D printing?

A: Vacuum casting allows for cost-effective replication of resin models, while SLS 3D printing delivers high-strength PP prototypes. Together, they offer both precision and scalability.

Q: Can PP material be used in dental applications?

A: Yes, PP is lightweight, chemically resistant, and ideal for dental appliance housings and functional prototypes.

Q: What is the typical lead time for dental resin models?

A: Lead times are usually 7–12 business days, depending on design complexity.

Q: Do you support customized medical device production?

A: Yes, we provide OEM and ODM services for dental labs, clinics, and medical device companies.

|

|

Dental Resin Vacuum Casting PP Material 3D Printing | Professional SLS Printing Service Images |